Very delicate cleaning processes demand critical examination of the entire system and process engineering in conjunction with relevant environmental factors in any form. The yardstick represents the relevant undesired impurities (particulate, organic or biological). For this, LPW also offers new and innovative methods, in addition to familiar cleaning and drying methods.

TASKS AND SOLUTIONS

For many applications, conventional plant systems with proven cleaning processes (e.g. ultra/mega sound applications) are no longer sufficient. With our know-how from other industries and our new high-performance processes (e.g. CNp), we are able to design systems with high filtration rates using known flood and spray cleaning processes.

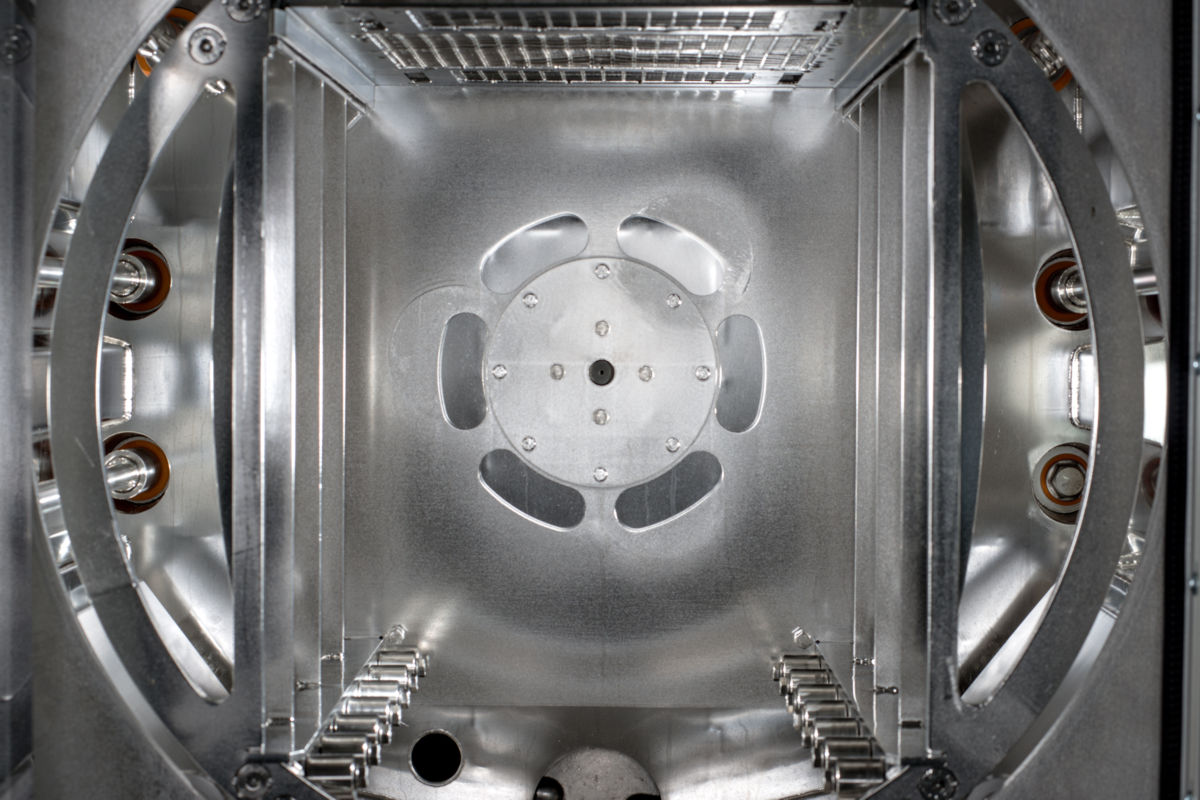

Combined with hermetically sealed working chambers that eliminate environmental contaminants, high purity requirements can be met. The use of physical factors such as pressure/vacuum, temperature change or volume flow also opens a wide range of process engineering options for optimising or increasing the efficiency of the cleaning process. These are continuously developed by our process development department in direct cooperation with our customers.

We have extensive experience in intermediate and final cleaning of, for example.

- Parts and components in the semiconductor manufacturing environment (valves, tubes, cooling elements, etc.)

- Medical components after machining or surface treatment and forming processes.

- Optical components (e.g. laser and sensor technology)

- Micro structured fine mechanical components

We would be pleased to show you reference examples!